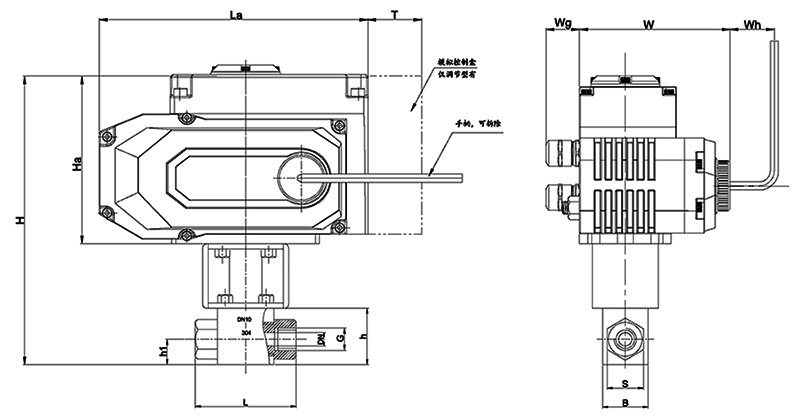

閥體尺寸(mm)

公稱壓(bar) | 型號規(guī)格 | 通徑 DN | G | L | h | h1 | B | S | H | Ha | La | T注 | Wg | W | Wh |

≤PN64 ? | OSAQ91108 | 8 | 1/4” | 69 | 34 | 16 | 28 | 22 | 207 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91110 | 10 | 3/8” | 75 | 42 | 19 | 34 | 27 | 215 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91115 | 15 | 1/2” | 84 | 46 | 21 | 38 | 30 | 219 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91120 | 20 | 3/4” | 98 | 53 | 24 | 44 | 36 | 226 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91125 | 25 | 1” | 114 | 63 | 29 | 55 | 46 | 236 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91132 | 32 | 1-1/4” | 130 | 80 | 34 | 65 | 55 | 256 | 128 | 166 | 40 | 25 | 124 | 35 |

OSAQ91140 | 40 | 1-1/2” | 150 | 90 | 41 | 84 | 65 | 289 | 133 | 200 | 40 | 25 | 140 | 35 |

OSAQ91150 | 50 | 2” | 172 | 105 | 47 | 95 | 80 | 304 | 133 | 200 | 40 | 25 | 140 | 35 |

公稱壓(bar) | 型號規(guī)格 | 通徑 DN | G | L | h | h1 | B | S | H | Ha | La | T注 | Wg | W | Wh |

100≤PN ≤320 ? | OSAQ91108 | 8 | 1/4” | 69 | 34 | 16 | 28 | 22 | 207 | 125 | 142 | 40 | 25 | 112 | 35 |

OSAQ91110 | 10 | 3/8” | 75 | 42 | 19 | 34 | 27 | 215 | 125 | 142 | 40 | 25 | 140 | 35 |

OSAQ91115 | 15 | 1/2” | 84 | 46 | 21 | 38 | 30 | 219 | 125 | 142 | 40 | 25 | 124 | 35 |

OSAQ91120 | 20 | 3/4” | 98 | 53 | 24 | 44 | 36 | 229 | 128 | 166 | 40 | 25 | 112 | 35 |

OSAQ91125 | 25 | 1” | 114 | 63 | 29 | 55 | 46 | 262 | 133 | 200 | 40 | 25 | 112 | 35 |

OSAQ91132 | 32 | 1-1/4” | 130 | 80 | 34 | 65 | 55 | 279 | 133 | 200 | 40 | 25 | 140 | 35 |

OSAQ91140 | 40 | 1-1/2” | 150 | 90 | 41 | 84 | 65 | 318 | 162 | 235 | 40 | 25 | 156 | 35 |

OSAQ91150 | 50 | 2” | 172 | 105 | 47 | 95 | 80 | 333 | 162 | 235 | 40 | 25 | 156 | 35 |

備注:①電動執(zhí)行器(簡稱電動頭)的尺寸��,請另查閱執(zhí)行器資料���,以上為設(shè)計尺寸,與實物可能存誤差���。?

②如果是選擇技術(shù)參數(shù)中的特選項目或客戶有特制要求時�,請向我們另行索取尺寸表;

③執(zhí)行器型號為常規(guī)配置���,若用戶氣源及工況條件較好����,則可優(yōu)化執(zhí)行器配置減少成本�,若工況條件差,則需加大執(zhí)行器規(guī)格���。